En la industria de la construcción en constante evolución, los edificios prefabricados destacan y redefinen nuestra comprensión y implementación de proyectos de construcción. Pero, ¿qué hace exactamente que sea una solución más inteligente en el presente? Vamos’ s profundizar en los puntos clave.

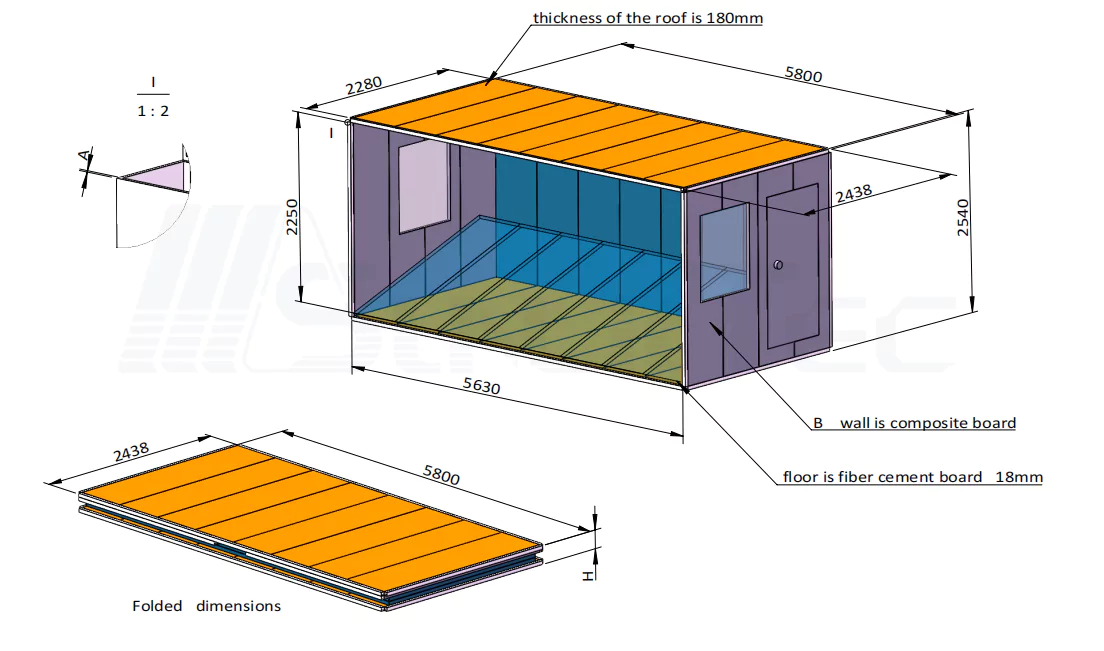

Edificios prefabricados Los edificios prefabricados son una forma de construcción en la que los componentes de edificios se fabrican primero en un entorno de fábrica controlado y luego se transportan al sitio de construcción para su montaje. Los componentes cubren paneles de pared, vigas y columnas, e incluso todo el módulo de la habitación. A diferencia de la construcción tradicional en el sitio donde todo se construye desde cero en el sitio, los edificios prefabricados dividen el proceso en dos etapas principales: la prefabricación fuera del sitio y el montaje en el sitio. Esta diferencia fundamental sienta las bases de su ventaja inteligente.

Inteligencia en el proceso de producción: precisión en el final de la fábrica

(1) La integración del diseño digital y la construcción colaborativa de fabricación tecnología de modelado de información (BIM) Ha provocado cambios. En la fase de diseño, crea un modelo digital 3D de todo el edificio, que no solo presenta visualmente la estructura, sino que también descompone con precisión el edificio en componentes individuales. Por ejemplo, al diseñar casas prefabricadas, BIM puede determinar el tamaño, el material e incluso la secuencia de instalación de cada panel de pared, viga y columna. En el extremo de fabricación, este modelo digital es el diseño. El equipo de control numérico (NC) en la fábrica produce componentes basados en los datos del modelo, y el error de dimensión clave se puede controlar en unos pocos milímetros, lo que es una precisión que la construcción tradicional en el sitio que se basa en el trabajo manual no puede lograr. De esta manera, los componentes se pueden montar sin problemas en el sitio, reduciendo el retraso y el retraso.

(2) Las fábricas que producen componentes prefabricados a través de procesos de producción automatizados se están automatizando cada vez más. Tomando la producción de losas de hormigón prefabricadas como ejemplo, el brazo robótico cortará y doblará con precisión las barras de acero de acuerdo con el modelo BIM; A continuación, el sistema automatizado vierte hormigón para garantizar una distribución uniforme y una vibración adecuada; A continuación, los componentes entran en la sala de curado automatizada, donde la temperatura y la humedad se controlan con precisión para garantizar la resistencia y la durabilidad del hormigón. En comparación con el vertido tradicional en el sitio, que se ve fuertemente afectado por el clima, depende en gran medida del trabajo manual y experimenta fluctuaciones significativas de calidad, la automatización de la fábrica tiene una mayor eficiencia de producción y una mejor consistencia. También puede acortar significativamente el tiempo de producción de componentes y reducir el desperdicio de materiales.

Proceso de construcción inteligente: montaje eficiente en el sitio

(1) El ensamblaje rápido modular de componentes prefabricados es como bloques de construcción gigantes. Después de ser transportado al sitio de construcción, se puede montar rápidamente con la ayuda de grúas y tecnología de conexión profesional. Por ejemplo, la construcción de un edificio de apartamentos prefabricado de varios pisos con aislamiento y paneles de pared de cableado, conectados con manguitos de lechado, puede garantizar la estabilidad estructural y es sencilla y rápida. Los datos muestran que para edificios de la misma escala, el período de construcción de los edificios prefabricados es un 30% -50% más corto que el de los edificios tradicionales. Esto tiene ventajas significativas para proyectos con plazos ajustados, como: Vivienda de emergencia y proyectos comerciales.

(2) La gestión inteligente de la construcción de sitios de construcción prefabricados también se ha vuelto más inteligente debido al Internet de las Cosas (IoT) y las aplicaciones móviles. Los componentes pueden estar equipados con sensores para monitorear en tiempo real la posición, el estado y el progreso de la instalación. El gerente del proyecto puede acceder a los datos y supervisar remotamente la construcción con su teléfono móvil. Si hay un retraso en el transporte o la instalación de componentes, se pueden tomar medidas correctivas inmediatamente para reducir los retrasos y errores de construcción, haciendo que el proceso de construcción sea más eficiente y predecible.

Garantía de calidad y seguridad

(1) La fábrica produce componentes prefabricados con calidad estable del componente, entorno controlable y estricto control de la temperatura, la humedad y los procesos de producción. Al igual que los componentes prefabricados de hormigón, las inspecciones de fábrica son más completas que las inspecciones in situ, lo que resulta en una calidad de componentes más alta y más estable, mejorando la seguridad estructural general de los edificios.

(2) Mejora de la seguridad de la construcción: Se completa una gran cantidad de trabajo en la fábrica, principalmente para el montaje en el sitio, reduciendo las operaciones a alta altitud y los procesos peligrosos (como la manipulación de materiales pesados en condiciones inestables). Ha habido una reducción significativa en los accidentes de seguridad como caídas y manipulación de materiales, lo que lo hace más seguro para los trabajadores.

Los edificios prefabricados, con el avance de la tecnología de producción y construcción, resuelven puntos dolorosos de la industria como la protección del medio ambiente, la calidad y la seguridad, se integran en edificios inteligentes y la ecología urbana y se convierten en una solución de edificios más inteligente hoy en día. A pesar de los desafíos como las normas técnicas y la conciencia del mercado, la innovación continua y la expansión de las aplicaciones hacen que el futuro sea lleno de esperanza. Con el desarrollo, los edificios prefabricados continuarán remodelando la industria de la construcción, proporcionando opciones de construcción más eficientes, sostenibles e inteligentes para diversas necesidades.