Shipping container houses vs prefabricated container houses – Differences in production processes

In the field of container houses, shipping container houses and prefabricated container houses have their own characteristics due to different production processes. The following is a detailed introduction to the differences in the production processes of the two.

- 1. Production of prefabricated container houses

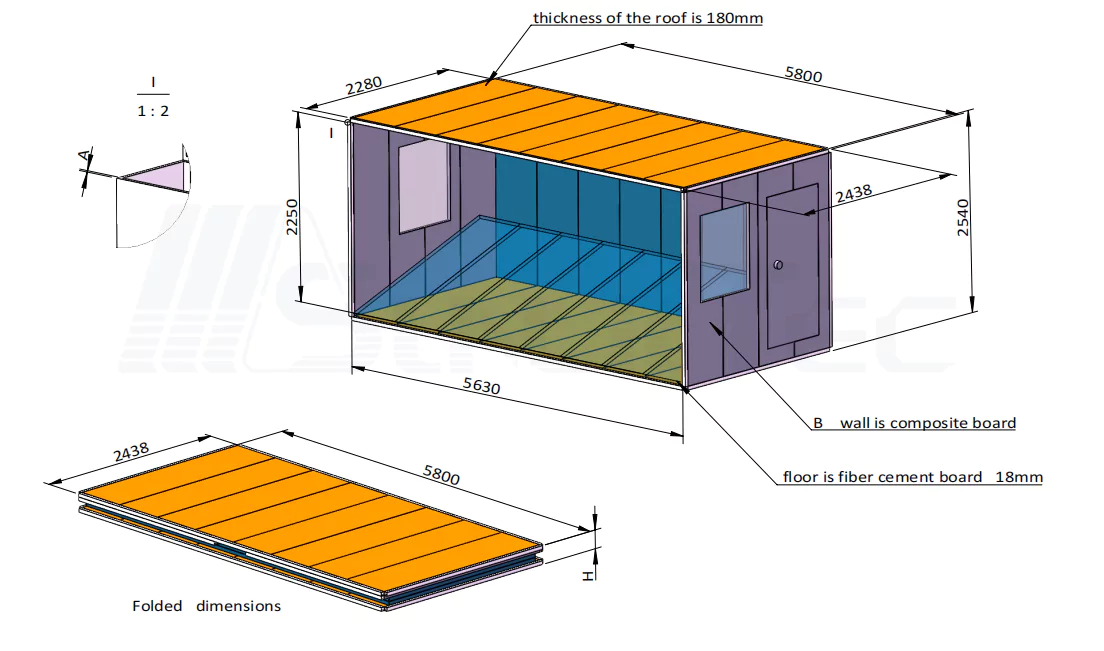

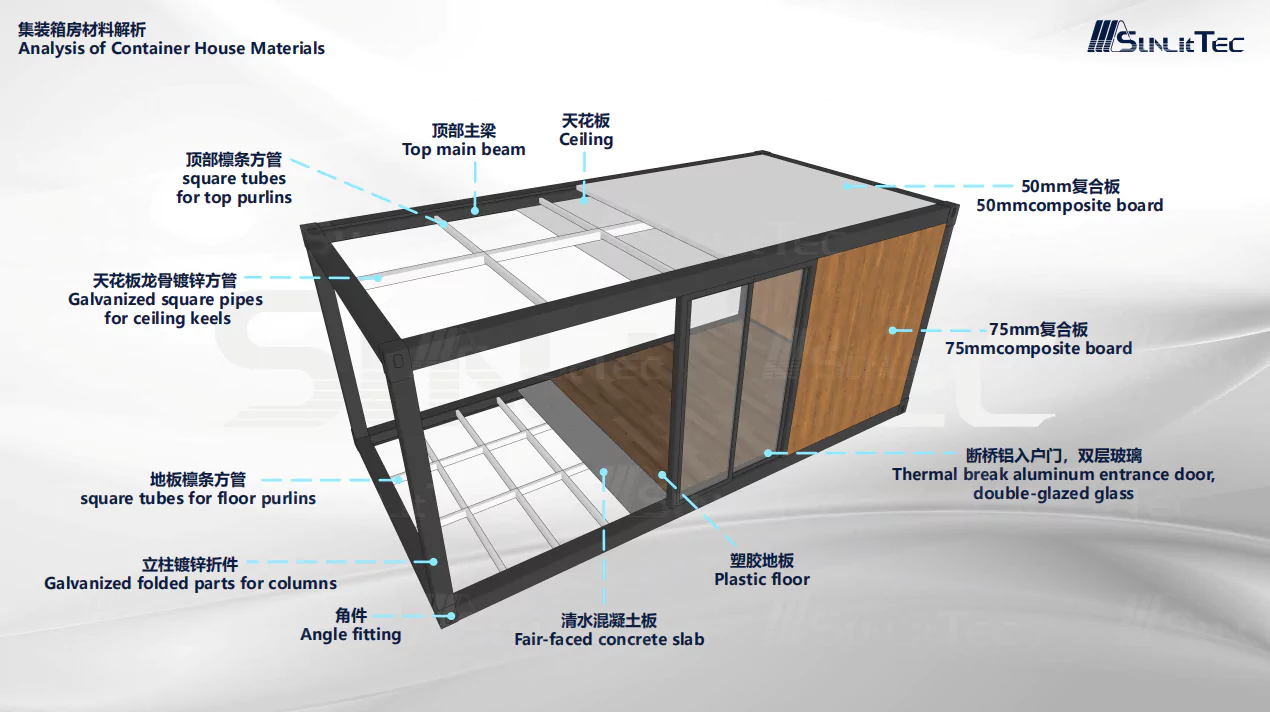

Ⅰ. Modular assembly from scratch: prefabricated container houses are completely composed of scattered parts. The production process is a “zero-to-whole” process from skeleton welding, insulation layer laying to shell assembly. This production method is like building blocks. Each component is produced independently and then precisely spliced. It has high flexibility and can customize houses of different specifications and functions according to needs.

Ⅱ. Strictly controlled core structure and customized configuration: SUNLIT TEC prefabricated container houses, whose internal steel structure uses high-strength galvanized steel pipes, are tightly combined through full welding technology to ensure that the structure is stable and durable. The insulation layer is combined with the local temperature and regulatory requirements of the customer to select the appropriate material and thickness. For example, thick rock wool boards are used in cold areas, and polyurethane foam boards with good thermal insulation performance are used in hot areas. The outer shell uses galvanized iron plate, and can also be sprayed with anti-corrosion paint according to customer preferences, taking into account both beauty and protection.

Ⅲ. Standardized production and environmental protection concept: The parts of SUNLIT TEC prefabricated container houses are either produced by themselves or purchased in a unified manner. During construction, the raw materials are cut according to the specified size with high precision, which greatly reduces the generation of waste, saving costs and complying with environmental protection concepts.

- Production of shipping container houses

Ⅰ. Pretreatment before the transformation of old boxes: To produce shipping container houses, you must first purchase second-hand shipping containers and thoroughly clean them after transporting them to the factory. This step requires careful inspection of the box body and handling of defects. If there is rust, grind and remove the rust; if there are dents, repair or replace the steel plate as appropriate to ensure that there are no obvious problems with the box body. After cleaning, use the inner primer to paint the wooden floor that comes with the container to isolate the old floor from the subsequent newly laid floor structure to avoid affecting the overall performance of the house.

Ⅱ. Structural transformation and reinforcement: After completing the pretreatment, the container must be metal processed and reinforced with structural steel. In the parts where doors, windows and vents are required, the steel plates are cut. In order to ensure the strength of the box structure, steel bars will be welded on the edge of the metal cut to prevent damage to the structure.

Ⅲ. Paint in advance to avoid pollution: After the metal parts are modified, the exterior walls of the container are painted before entering the roughcast construction stage. This can prevent paint from splashing into unnecessary areas during subsequent construction, reduce cleaning and repair work, and make the paint surface more uniform and beautiful.

Ⅳ. Electrical system installation: After the frame modification and exterior wall painting are completed, the electrical system is installed. According to the specifications, the power sockets and switches are reasonably arranged inside the house, and embedded LED ceiling lighting is installed. The power supply is uniformly supplied by the external circuit breaker panel to ensure the safety of electricity use.

Ⅴ. Construction of water supply and drainage system: Install PEX pipes as water supply pipes, PVC drainage systems for sewage discharge, and connect black water (toilet sewage) and gray water (washing, kitchen sewage) drainage pipes to the RV connection device or sewage pipe system to meet daily water and drainage needs.

Ⅵ. Insulation layer construction: After the electrical and plumbing systems are installed, spray foam insulation on the walls and ceilings. This material can fit tightly to the box, effectively block heat transfer, and improve the thermal insulation performance of the house.

Ⅶ. Interior decoration and finishing: After the container blank is completed, it is transported to the woodworking shop for final manufacturing and finishing. First install the lap board or gypsum board on the wall and ceiling, then install the decorative strips on the wall, floor and ceiling, and then repaint it to make the surface smooth and beautiful. Finally, install ceiling decorations such as ceiling fans, fire/CO2 detectors, LED lights, etc. to complete the construction of the entire house.

SUNLIT TEC has rich experience in the manufacture of shipping container houses and prefabricated container houses, and has a professional design team. Whether you want to transform an old box or customize a new prefabricated container house, you can create an ideal house effect for you.