Casa de contenedores El diseño se ha convertido en un área avanzada de la arquitectura modular. Equilibra la ecología, la eficiencia y la flexibilidad. Los problemas globales impulsan la demanda de nuevas opciones de vivienda. Estas opciones deben ser asequibles, móviles y respetuosas con el medio ambiente. Las casas de contenedores son un buen ejemplo. Pueden escalarse bien en hogares, negocios y edificios públicos. Esto demuestra su importancia en la planificación urbana futura.

Evolución del Diseño de Casa de Contenedores en Arquitectura Modular

El crecimiento del diseño de casas de contenedores en la arquitectura modular muestra un cambio en la forma en que vemos la vivienda, el respeto del medio ambiente y el uso del espacio. Comenzó como una solución simple para las necesidades a corto plazo. Ahora, se ha convertido en una tendencia arquitectónica avanzada. Esta tendencia se centra en nuevas ideas, fuerza y cuidado del medio ambiente.

Contexto histórico de los contenedores en la arquitectura

La gente primero usó contenedores de envío para hogares y espacios de negocios por necesidad.

Los primeros cambios en los contenedores ISO para viviendas urgentes y a corto plazo provinieron de la recuperación de desastres y los campamentos de trabajadores en los sitios. Estas unidades permitieron una configuración rápida, bajo costo y reutilización. Tales rasgos eran muy útiles en situaciones de ayuda.

Con el tiempo, los diseñadores comenzaron a probar el cuerpo de acero duro de los contenedores. No sólo lo utilizan con fines básicos. En cambio, también lo conformaron para el estilo.

El cambio de uso básico a nuevas ideas arquitectónicas ocurrió cuando personas inventivas convirtieron estas unidades de trabajo en áreas de vida animadas, pequeños espacios de oficina e incluso lugares de hotel.

Este cambio coincidió con el aumento del aspecto post-industrial en la planificación urbana. Los lados de acero liso, los patrones ondulados y las formas sencillas en las casas de contenedores encajan bien con los gustos de diseño actuales.

Cambio de percepciones y demanda del mercado

A medida que aumentaba la preocupación por el medio ambiente y las multitudes de la ciudad, la casa de contenedores se convirtió en más que una solución rápida. Se convirtió en una forma de vida.

Vida Sostenible: Las casas móviles tienen las características de ser reutilizables y reducir los residuos de construcción, que cumplen con los requisitos de las políticas de protección ambiental.

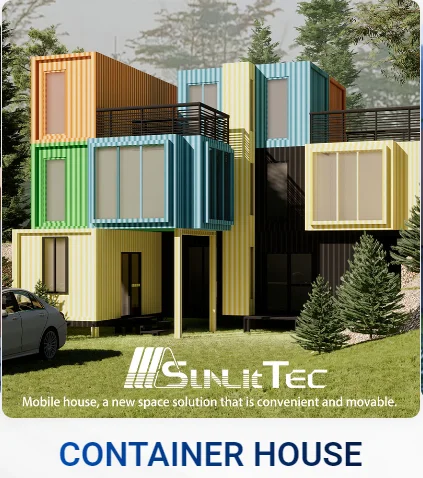

Vivienda Urbana Compacta: Con los altos costes de la tierra, las ciudades se están volviendo a opciones de vivienda compactas y eficientes como combinaciones de contenedores personalizadas adecuadas para pequeños edificios de apartamentos o espacios comerciales creativos.

Influencia de los medios: Plataformas como Instagram y YouTube han mostrado conversiones de contenedores elegantes a nivel mundial, convirtiéndolos en viviendas aspiracionales en lugar de opciones de reserva.

Innovaciones arquitectónicas en el diseño de casas de contenedores

Los constructores en arquitectura han asumido la tarea de trabajar con los límites de los contenedores de envío. Utilizan mejores métodos de ingeniería. Estos mantienen la forma y el propósito intactos.

Ingeniería estructural y estrategias de carga

Los contenedores de envío se hacen para apilarse durante el viaje. Pero los cambios en su estructura pueden debilitarlos.

Refuerzo: El corte en las paredes del contenedor puede comprometer su capacidad de carga. A menudo se requieren refuerzos utilizando marcos de acero o refuerzos internos para mantener la integridad estructural.

Construcción híbrida: El uso de madera laminada cruzada (CLT) o paneles reforzados con fibra de vidrio puede complementar la carcasa de acero para mejorar la resistencia sísmica y el aislamiento.

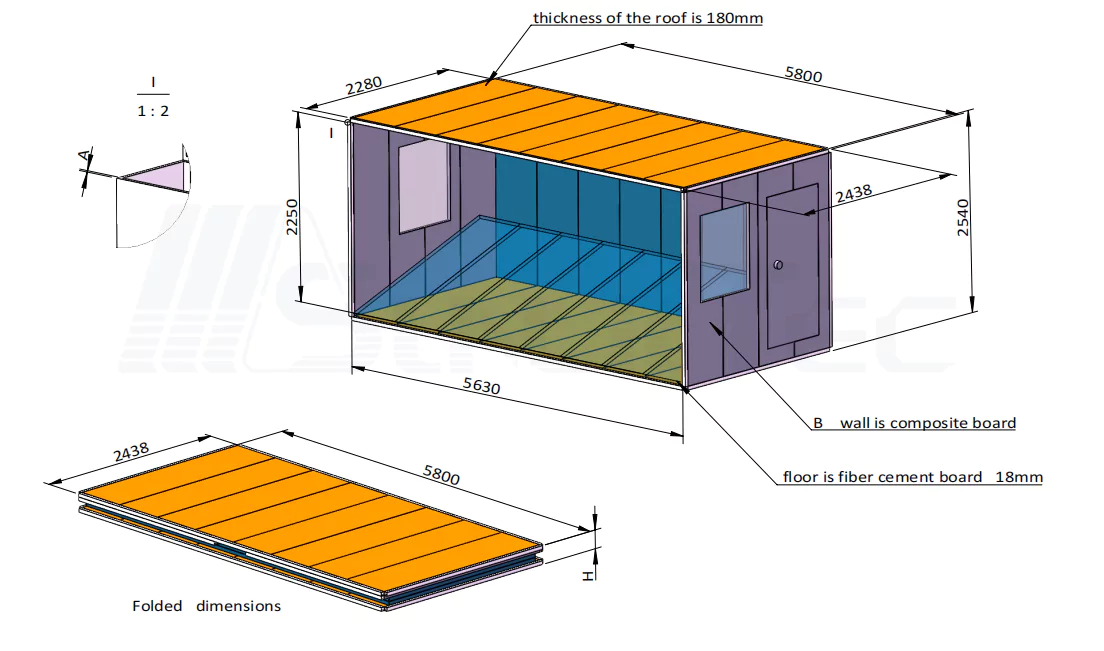

Configuración de múltiples unidades: Los ingenieros diseñan sistemas de soporte que permiten que los contenedores sean en voladizo o apilados en múltiples pisos de altura sin comprometer la seguridad.

Tecnologías de rendimiento térmico y aislamiento

El acero pasa el calor fácilmente. Esto crea problemas para mantener las áreas interiores cómodas durante todo el año.

Puente térmico: La conductividad del acero requiere interrupciones térmicas para prevenir la pérdida o ganancia de calor.

Materiales de aislamiento: La capa de aislamiento adopta la calificación de fuego de poliuretano para lograr la no inflamabilidad; Todos los materiales internos están hechos de materiales respetuosos con el medio ambiente para garantizar su seguridad.

Principios de diseño pasivo: La colocación de ventanas para la ventilación cruzada y el uso de sobresalientes o aletas verticales para sombrear interiores ayudan a minimizar las demandas de energía.

Integración con sistemas Smart Home

Hoy’ Las casas de contenedores ahora incluyen herramientas conectadas a Internet. Estos coinciden con lo que se encuentra en casas normales.

Los arneses de cableado modulares simplifican la instalación a través de módulos prefabricados.

Los sensores de control climático regulan la temperatura interna en función de los patrones de uso.

Las plataformas inteligentes centralizadas ofrecen el control de la iluminación, los sistemas de seguridad y los electrodomésticos, ideales para entornos compactos como los encontrados en la serie Apple Cabin de Sunlit Tec.

Sostenibilidad y consideración ambiental

El estilo modular de las casas de contenedores ayuda naturalmente a los hábitos de construcción verde.

Evaluación del ciclo de vida de las casas de contenedores

- Reuso del material: La renovación estándar del contenedor conserva la robusta carcasa metálica y rediseña el interior para separar espacios funcionales.

- Bajos residuos: la prefabricación reduce los residuos de construcción en el sitio y permite un control de calidad consistente.

- Activos reubicables: las casas de contenedores se pueden desmontar y mover sin demolición, lo que amplía la usabilidad en todos los sitios.

Sistemas Eficientes Energéticamente e Integración Renovable

Los techos listos para uso solar y las instalaciones de recogida de agua de lluvia son ahora partes clave de los planes de viviendas de contenedores:

| Características | Descripción |

| Paneles solares fotovoltaicos | Montado en techos planos o toldos |

| Recolección de agua de lluvia | Integrado en diseños de techos inclinados |

| Almacenamiento fuera de la red | Los bancos de baterías permiten la independencia energética |

Las características fuera de la red a través del almacenamiento de baterías y configuraciones de energía mixta se adaptan bien a áreas lejanas o de riesgo.

Flexibilidad de diseño y estrategias de planificación espacial

Incluso con tamaños fijos, las casas de contenedores permiten grandes cambios.

Configuraciones modulares para diversas aplicaciones

- Micro Casas: Unidades de contenedor único como Modelo C1 de Sunlit Tecofrece 13m² ideal para vivir en solitario.

- Unidades familiares: configuraciones de dos pisos como B7 maximizan el espacio vertical con balcones y múltiples habitaciones.

- Casos de uso comercial: pueden servir como tiendas móviles, puestos de exposiciones o oficinas en áreas turísticas.

Soluciones de diseño de interiores para entornos espaciales limitados

La planificación inteligente es clave cuando se trata de cajas metálicas.

Técnicas de optimización del espacio vertical

Camas elevadas y niveles superiores son comunes. Por ejemplo, la cápsula V3 de Sunlit Tec tiene una configuración de dos pisos. Proporciona 20.3m² en la planta baja y 12.5m² por encima. Esto lo hace sin aumentar el área de base.

Integración de muebles multifuncionales

Mesas plegables, camas de pared o lugares de almacenamiento secretos hacen que las tareas cotidianas sean más suaves en espacios estrechos. Los planes a menudo se adaptan a los deseos del usuario durante el trabajo de fábrica.

Marcos Regulatorios y Cumplimiento del Código de Construcción

Aunque llenas de promesas, las casas de contenedores encuentran obstáculos oficiales.

Navegando por las leyes de zonificación y permitiendo desafíos

Las regulaciones varían entre estados y municipios.

Las estrategias incluyen alinear unidades con códigos de unidades de vivienda accesorias (ADU) o usar clasificaciones de viviendas móviles.

Los clientes necesitan informarnos de los requisitos especiales para pequeñas casas en la zona local, lo que facilitará nuestro diseño específico de las líneas de agua y electricidad.

Cumplimiento con los códigos de seguridad estructural y contra incendios

- Los recubrimientos a prueba de fuego son obligatorios en las superficies internas de acero.

- La ventilación adecuada, las ventanas de salida y la accesibilidad (ADA) deben incorporarse durante las etapas de diseño.

Tendencias globales que influyen en la adopción de casas de contenedores

Las casas de contenedores tienen diferentes niveles de uso en todo el mundo. Esto depende de las cuestiones monetarias, el clima y las reglas.

Variaciones regionales en las tasas de adopción y casos de uso

- En los países desarrollados: Popular como viviendas urbanas de moda o alquileres Airbnb.

- En las regiones en desarrollo: Se utilizan como residencias temporales y oficinas para sitios de construcción o refugios en campamentos de refugiados.

- Los gobiernos han apoyado iniciativas de vivienda modular después de los desastres debido a la facilidad de despliegue.

Influencia de las condiciones climáticas en las adaptaciones del diseño

- Aislamiento más grueso (> 150 mm)

- Sistemas de calefacción por suelo

- Diseño hermético con barreras de vapor

Adaptaciones al clima caliente

Dispositivos de sombreado externos

Revestimientos reflectantes en techos

Ventilación cruzada mejorada a través de la colocación de la ventana

Tecnologías emergentes que dan forma al futuro de la arquitectura de contenedores

Nuevas ideas continúan impulsando lo que podemos hacer con los contenedores de envío.

Integración de impresión 3D con marcos modulares

La impresión 3D está bajo prueba para capas exteriores, paredes o bonitos frentes. Reduce los materiales residuales. Al mismo tiempo, aumenta la apariencia.

Técnicas avanzadas de prefabricación

Herramientas como corte controlado por computadora, modelos digitales y soldadura por robot permiten:

Ciclos de producción más rápidos.

Renderings personalizados basados en la entrada del cliente (como ofrece Sunlit Tec)

Sunlit Tec conduce en casa de contenedores nuevas ideas. El empresa enfatiza la ingeniería exacta, el cuidado del medio ambiente y el aspecto fino. Proporciona soluciones modulares listas para usar adaptadas a muchas necesidades del cliente. Sus productos van desde pequeños microhogares hasta edificios de cápsulas altos con herramientas inteligentes. Cada pieza se fabrica en la fábrica. Incluye tuberías, cables, muebles y control de aire para una configuración rápida del sitio. Esto a menudo dura solo dos horas después del parto. Con su trabajo en Europa, el sudeste asiático y América del Norte, Sunlit Tec da forma a las conversaciones sobre la vida modular verde en todo el mundo. Lo hace a través del enfoque en nuevas formas y planes centrados en el usuario.

Preguntas frecuentes

Q1: ¿Son las casas de contenedores lo suficientemente duraderas para la vida a largo plazo?

R: Sí. Cuando se refuerzan y aislan adecuadamente, las casas de contenedores pueden igualar o superar la vida útil de los edificios tradicionales. Muchos modelos utilizan marcos de acero galvanizado clasificados para el nivel de resistencia sísmica 10 y el nivel de resistencia al viento 12.

Q2: ¿Se pueden personalizar las casas de contenedores para ajustarse a la estética personal?

R: Absolutamente. Los clientes pueden personalizar según sus necesidades específicas para satisfacer diferentes propósitos y requisitos funcionales. Desde acabados exteriores hasta diseños interiores, empresas como Sunlit Tec ofrecen una personalización completa, incluyendo renderizaciones antes de que comience la fabricación.

Q3: ¿Cuál es la ventaja de costo promedio en comparación con la vivienda tradicional?

R: El precio de las casas de pensión B1 es solo un tercio de él [casas tradicionales], lo que reduce en gran medida el costo de la construcción de casas. Esta asequibilidad los hace atractivos para proyectos turísticos, empresas nuevas o soluciones de vivienda asequibles.