مع تحرك صناعة الإسكان العالمية نحو أساليب بناء مستدامة وفعالة من حيث التكلفة ، أصبحت المنازل الموحدة حلا شائعا. منازل الحاويات هي مثال رائع. بالنسبة لكل من المطورين والأفراد ، توفر هذه المنازل النشر السريع والتصاميم الحديثة والبصمة البيئية الأصغر. ومع ذلك ، توجد شبكة معقدة من التحديات اللوجستية وراء الجاذبية ، والتي يجب على المصنعين التعامل معها لضمان التسليم والتركيب السلس. من مصادر الحاويات الصلبية إلى الاتصالات النهائية للمرافق في الموقع ، تتطلب كل مرحلة تنسيق دقيق. تتناول هذه المقالة هذه المشاكل اللوجستية العالمية وتستكشف كيف تقوم شركات مثل Sunlit Tec بإنشاء طرق جديدة لحلها.

تعقيدات سلسلة التوريد العالمية في تصنيع الحاويات المنزلية

يتأثر إنشاء منازل الحاويات بشكل كبير بديناميكات سلسلة التوريد العالمية. وفي الواقع، تتطلب هذه العملية تنسيقا دقيقا عبر القارات والصناعات.

المكونات الرئيسية في سلسلة التوريد المنزلية للحاويات

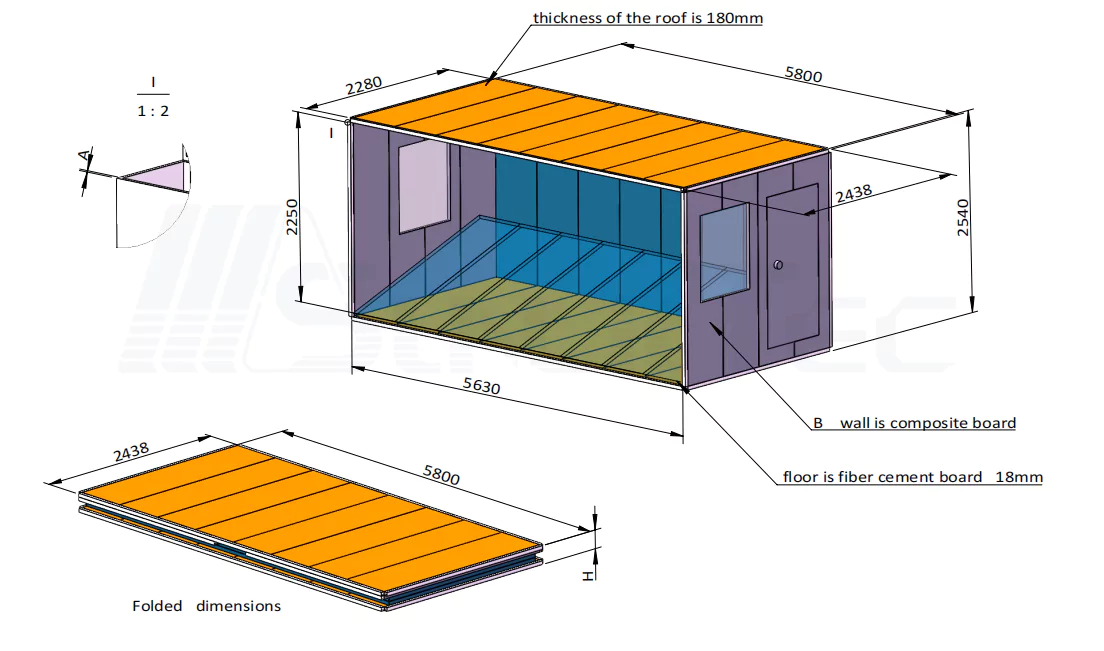

أولاً، تتضمن العملية العثور على المواد الأساسية مثل الحاويات الفولاذية والتعزيزات الهيكلية، والتي غالباً ما تشتري من أسواق دولية مختلفة بناءً على التكلفة والتوافر وقواعد التجارة. معظم المنازل المتنقلة بنيت مع تصميم وحدات، حيث كل جزء يعمل مثل منفصل “ كتلة بناء. ” وهذا يسمح للأجزاء أن تكون مسبقة التصنيع في المصنع. ثم يتم نقلها إلى الموقع للتجميع السريع. ما’ أكثر من ذلك ، تدعم هذه الطريقة كل من شحن الوحدة بأكملها وتفكيك الوحدات لتتناسب مع المتطلبات اللوجستية.

بالإضافة إلى المواد الخام ، يجب على سلسلة التوريد أيضًا مزامنة عمل فرق التصميم ومصانع التصنيع وورش العمل الخاصة بالتخصيص. وقد تكون هذه الوحدات في بلدان مختلفة. وبالتالي فإنها تتطلب إشرافا مستمرا وإجراءات موحدة. مراقبة الجودة في كل خطوة أمر حيوي للغاية للحفاظ على السلامة الهيكلية والسلامة والجاذبية البصرية.

عقبات الشحن والنقل الدولي

غالبا ما يواجه المصنعون تأخيرات كبيرة في الشحن. وتأتي هذه من الموانئ المزدحمة أو الاحتجازات الجمركية أو نقص حاويات الشحن. في حين أن القدرة على التصدير في شكل حاويات تساعد على خفض تكاليف الشحن ، إلا أن هذه الفوائد يمكن أن تفقد بسبب انقطاع المرور العابر بسبب القضايا الجيوسياسية أو الكوارث الطبيعية.

طرق التعبئة والتغليف تلعب دورا كبيرا هنا. التصميم المكون من وحدات يجعل التحرك والإعداد أكثر ملاءمة ، مما يسمح بتفكيك وتجميع بسيطة حسب الحاجة. بالإضافة إلى ذلك ، تساعد وحدات الشحن في نمط حزمة مسطحة على تقليل الضرر أثناء النقل مع السماح أيضًا بترتيبات التحميل المرنة.

تنسيق الموردين عبر الحدود

يجب على المصنعين إدارة أوقات التسليم المختلفة من موردي المكونات ومزامنة التسليمات مع جداول الإنتاج. هذا’ وظيفة كبيرة. الحواجز اللغوية، والاختلافات في المناطق الزمنية، والاتصالات المتباينة غالبا ما تجعل العمل مع البائعين الأجانب أكثر صعوبة.

الحل لهذا مرة أخرى هو الأوراق الموحدة ، مثل دليل التثبيت الشامل والنماذج الجمركية. يمكن تصدير منازل الحاويات بكميات كبيرة ثم تقسيمها على وحدات ، وهي عملية تجعل النقل أكثر مرونة. ومع ذلك، وبدون وجود أنظمة متسقة لتوثيق وتتبع المشاريع، يمكن أن تتمدد التأخيرات عبر سلسلة التوريد بأكملها.

تحديات النشر في الموقع لمنازل الحاويات الموحدة

في حين أن الخدمات اللوجستية العالمية تهيئ المسرح، فإن نجاح تركيب منزلي وحدات يعتمد على التغلب على المشاكل المحددة للموقع. الكثير يمكن أن يخطئ.

متطلبات إعداد الموقع

قبل ظهور أي وحدات، يجب أن تلبي الأساس قواعد السلامة الهيكلية. يتم حظر أسس الحصى بسبب مخاطر التآكل. بدلاً من ذلك ، تحتاج إلى أسطح جامدة مثل وسائد الخرسانة أو قواعد الأسمنت مع المسامير الموجودة فيها. على أرض منحدرة أو غير متساوية ، يضمن تركيب الأعمدة الخرسانية وضعًا مستويًا ويمنع استقرار الهيكل على مدى فترة زمنية. وتحقيقا لهذه الغاية ، تساعد Sunlit Tec العملاء في تحديد أنسب نوع من الأساس للأرض التي يوجدون عليها ، مما يزيد من تحسين السلامة وزيادة سهولة التركيب.

وحدات النقل وتحديد المواقع في الموقع

المسائل اللوجستية لا’ t توقف بعد التسليم. غالبا ما يتطلب نقل وحدات الحاويات الكبيرة الحجم عبر الطرق الضيقة أو المناطق البعيدة مركبات خاصة وتخطيط الطرق بدقة. بعد ذلك ، يجب على الرافعات أو الرافعات الشوكية رفع ووضع كل وحدة بدقة. هذه مهمة أصبحت أكثر صعوبة بسبب الطقس مثل الرياح القوية أو المطر. تصميم وحدات النماذج مثل منزل الحاويات C2 يسمح لتفكيكها ووضعها معا حسب الحاجة، مما يساعد على تبسيط التراكم في الموقع والمواءمة في حالات مختلفة ذات مساحة محدودة.

تكامل المرافق والامتثال المحلي

بمجرد تجميع الهيكل ، تتضمن الخطوة التالية اتصال المرافق المحلية: السباكة والأنظمة الكهربائية والتبريد والتكيف. في هذه العملية، يجب القيام بكل شيء وفقا لقوانين البناء المحلية ولوائح تقسيم المناطق. بما أن كل منطقة لها قواعدها ومواصفاتها الخاصة، فإن هذا يعني تلقائياً أن التصميم المكون من وحدات بحاجة إلى تكييف الموقع. واستكمالا لهذا ، تقدم Sunlit Tec أيضًا نماذج مناسبة لحلول خارج الشبكة ، مثل أنظمة الطاقة الشمسية أو إعدادات المقطورات المتنقلة حيث لا يمكن وضع أسس دائمة.

استراتيجيات لتحسين سلسلة التوريد المنزلية للحاويات

لجعل العمليات أكثر سلاسة من المصنع إلى التجميع النهائي ، يجب على المصنعين استخدام خطط استباقية تقلل من التأخيرات وتحسن التنسيق.

تبسيط الخدمات اللوجستية من خلال التنسيق المخطط له مسبقاً

وتتمثل إحدى التقنيات الرائعة في مطابقة جداول الإنتاج مع جداول الشحن الدولية في وقت مبكر من عملية التخطيط. وهذا يقلل من أوقات تخزين المخازن. كما أنه يتجنب مشاكل ازدحام الموانئ. علاوة على ذلك، يوفر استخدام أدوات سلسلة التوريد الرقمية تتبع في الوقت الفعلي للشحنات والمخزونات وأنشطة البائعين، مما يسمح بإصلاحات سريعة عندما تظهر المشاكل.

توطين التجميع عند الإمكان

ويمكن لإنشاء مراكز إقليمية للخطوات النهائية للتجميع أن يقلل إلى حد كبير من عبء النقل لمسافات طويلة. هذه المراكز مفيدة. كما يمكن أن تعمل كمراكز دعم حيث ينهي المقاولون المحليون التثبيتات النهائية أو اتصالات المرافق بشكل أكثر فعالية ، مما يؤدي إلى أوقات استجابة أسرع.

تحسين التواصل بين أصحاب المصلحة

وعليه، ينبغي للشركات أن تعتمد منصات مركزية لإدارة المشاريع لتجنب سوء الاتصال. توفر الأدوات موقعًا واحدًا لمشاركة المخططات والجداول الزمنية وأوراق الامتثال وأوامر التغيير. كما تضمن الاجتماعات على فترات منتظمة من العملاء والموردين وشركات اللوجستيات والسلطات المحلية أن الجميع على نفس الصفحة.

تسليط الضوء على Sunlit Tec كمورد موثوق به لمنزل الحاويات

من بين العديد من الشركات المصنعة للمنازل الحاويات العالمية، صنلايت تيك تبرز بسبب تنوعها في المنتجات والتزامها بالجودة والتخصيص المحدد للموقع. إنهم خيار رائع

نظرة عامة على قدرات Sunlit Tec ومجموعة المنتجات

Sunlit Tec لديها مجموعة واسعة من الوحدات المكونة من وحدات. وهذا يشمل نماذج مع شرفات ، والمنازل المتنقلة الصغيرة تسمى “ ؛ كبسولات الفضاء ” وهياكل من طابقين تخلط بين كفاءة المساحة والتصميم الجذاب. تركيزهم الرئيسي على سهولة التجميع ومرونة التصميم والمتانة الدائمة في العديد من البيئات المختلفة.

التزام بضمان الجودة ودعم العملاء

جميع هياكلها مصممة لتلبية معايير السلامة الدولية. إذا فشل جزء خلال فترة الضمان ، ستقوم الشركة بشحن مكون بديل. ومع ذلك ، من المهم ملاحظة أنه لا يقدم خدمات إصلاح في الموقع. يضمن هذا الوعد الموثوقية دون تعبئة المستخدمين بواجبات الصيانة المفاجئة.

خيارات التخصيص بناء على شروط الموقع

Sunlit Tec تعرف أن كل موقع مختلف. ولذلك، فهم توفير حلول مخصصة مثل قواعد الخرسانة الثابتة المسمار للاستقرار على الأرض المنحدرة أو تصاميم مثبتة على المقطورة للاستخدامات المتنقلة. يساعد فريقهم العملاء خلال عملية اختيار الأساس بأكملها بناءً على ميزات التضاريس الفريدة ، مما يضمن السلامة الهيكلية من البداية.

أفكار نهائية حول التغلب على حواجز النشر

الطريق من إنشاء المصنع إلى منزل وحدات صالح للعيش يتطلب تخطيط متزامن عبر القارات ومجالات الخبرة. إنها رحلة طويلة يتطلب النجاح التنسيق في مرحلة مبكرة بين فرق التصميم والموردين وشركات الشحن والمقاولين المحليين. لذلك، يجب على المصنعين إيجاد توازن بين كفاءة المصادر العالمية واستعداد النشر المحلي باستخدام التكنولوجيا وتشكيل شراكات إقليمية. اختيار مورد ماهر مثل Sunlit Tec يقلل بشكل كبير من المخاطر ، مما يجعلها شريك موثوق به للاحتياجات السكنية الحديثة.

الأسئلة الشائعة:

Q1: هل يمكن وضع منزل حاوية مباشرة على الحصى؟

ج: لا. لا ينصح بأسس الحصى بسبب التآكل المحتمل. هناك حاجة إلى سطح صلب ومستوى مثل قاعدة الخرسانة لضمان السلامة والاستقرار.

س2: هل يتم تضمين نظام مراقبة أو إنذار مع منازل حاويات Sunlit Tec؟

ج: لا. لا تثبت Sunlit Tec أنظمة المراقبة أو الإنذار في منازلها المكونة من وحدات كميزة قياسية. يمكن للعملاء إضافة هذه الأنظمة بنفسهم.

س3: ماذا يحدث إذا تضرر جزء خلال فترة الضمان؟

ج: إذا تضرر جزء خلال فترة الضمان ، فسترسل Sunlit Tec مكون استبدال. ومع ذلك ، لا تقدم الشركة خدمات الإصلاح.