ما هو بالتحديد البناء وحدات؟ إنها عملية يتم فيها صنع المبنى في أقسام داخل المصنع. هذه الظروف المراقبة تضمن الجودة. ما’ أكثر من ذلك ، تستخدم هذه المباني نفس المواد وتتبع نفس الرموز بالضبط مثل المنازل التقليدية. ميزة كبيرة هي السرعة. في كثير من الأحيان يقلل من وقت البناء إلى النصف. يعتمد تصميم معظم المنازل المتنقلة على فكرة التوحيد هذه ، حيث يعمل كل جزء مثل وحدة منفصلة “ كتلة بناء. ” ويمكن بناء هذه وتضميمها في المصنع، أو يمكن شحنها في وحدات منفصلة إلى الموقع لتجميع سريع وسهل.

التصنيع المسبق للمصنع: الميزات والمزايا

التصنيع المسبق للمصنع هو جزء مركزي من العملية الموحدة لأنه ينقل الكثير من العمل بعيدا عن موقع العمل.

ما هو التصنيع المسبق المصنع في البناء وحدات

التصنيع المسبق للمصنع يعني ببساطة جعل المبنى’ أقسام مختلفة في إعداد مسيطر عليه قبل نقلها إلى الموقع النهائي. الشيء الرائع في المنازل الجاهزة هو أن معظم العمل يتم في المصنع. ثم ، يمكن وضعها معا بسرعة كبيرة بعد الوصول إلى الموقع. هذه العملية توفر الكثير من الوقت وتكاليف العمالة. بالإضافة إلى ذلك ، فإنه يقلل من كمية الاضطرابات في موقع البناء.

تحسين مراقبة الجودة والتوحيد القياسي

العمل داخل المصنع يسمح بفحص الجودة الصعبة للغاية. وهذا يضمن أن التصنيع دائما عالية الجودة، وكل شيء يتبع خطط التصميم تماما، مما يساعد على تقليل الأخطاء في الموقع.

الكفاءة في جداول الإنتاج

يمكن إنجاز المشاريع بسرعة أكبر. هذا لأن العمال يمكنهم إعداد الأرض في نفس الوقت الذي يتم فيه بناء المنزل في المصنع. هذا العمل الموازي هو ميزة كبيرة. وبالتالي، فإنه’ مفيدة بشكل خاص للتطورات على نطاق واسع مع العديد من المنازل الجاهزة.

تقليل الاعتماد على العمل في الموقع والطقس

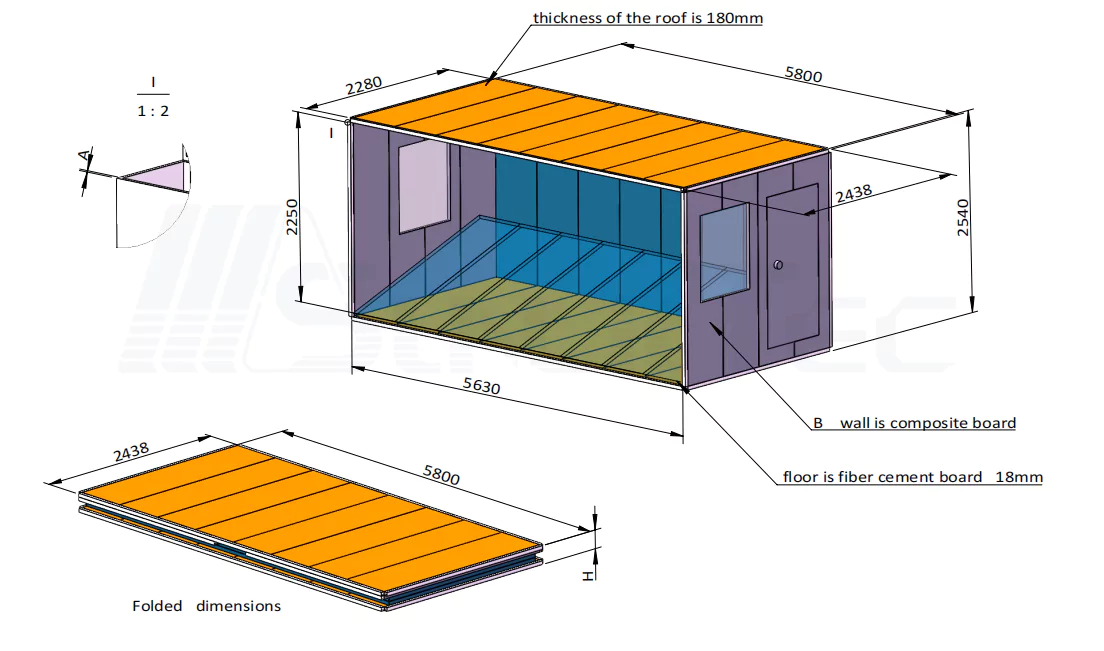

لا تتأثر الوحدات المصنعة بالطقس السيئ، لذلك فإن التأخيرات نادرة. كما أنها تتطلب عددًا أقل من العمال في العقار ، مما يساعد على تقليل المخاطر والتكاليف. على سبيل المثال، يتم تجهيز وحدات المباني على غرار الحاويات في الأماكن المغلقة. يحتاجون فقط إلى تجميع طوابق مختلفة في الموقع ، وهو نظام يبسط المهمة ويجعل فترة البناء أقصر بكثير.

التجميع في الموقع: الخصائص والفوائد

بعد صنع الوحدات ، يجب تجميعها على الممتلكات ، والتي تقدم مجموعة فريدة من الفوائد الخاصة بها.

دور التجميع في الموقع في المشاريع النموذجية

التجميع في الموقع هو الخطوة التي يتم فيها وضع وحدات جاهزة وموصلة في موقع المبنى. هذه العملية مهمة. يضمن أن الهيكل سليم ومتصل بشكل صحيح بجميع المرافق.

مرونة للتركيبات المعقدة أو المخصصة

تحتاج بعض المشاريع إلى لمسات خاصة أو تغييرات أسهل التعامل معها في الموقع. قد تشمل هذه التفاصيل المعمارية الفريدة من نوعها أو التصاميم التي يجب تعديلها لتضاريس محددة.

التكيف مع الشروط المحددة للموقع

التصميم الوحدي لهذا النوع من المنزل يجعل التحرك وإعداده أكثر ملاءمة بكثير. يسمح بسهولة الإزالة وإعادة الجمع اعتمادا على ما هو مطلوب. ما’ أكثر ، يمكن أن تتكيف بمرونة مع الاستخدامات المختلفة والحاجة إلى الانتقال. هذه القدرة على التكيف تجعل التجميع في الموقع خيار مثالي للخصائص الغريبة أو البعيدة.

التنسيق مع لوائح البناء المحلية

يضمن التجميع في الموقع أيضًا أن المبنى يلبي جميع القوانين والمعايير المحلية. هذه القواعد يمكن أن تختلف كثيرا من مكان إلى آخر.

مقارنة المصنع التجهيز المسبق والتجميع في الموقع

القرار بين العمل في المصنع والتجميع في الموقع ينخفض حقا إلى حفنة من العوامل المهمة.

كفاءة الوقت وتخطيط المشروع

التصنيع المسبق في المصنع عادة ما يؤدي إلى وقت الانتهاء الأسرع. هذا لأن عمل الموقع وبناء الوحدات يحدث في نفس الوقت. من ناحية أخرى ، يمكن للتجميع في الموقع تمديد الجدول الزمني ، خاصة إذا كان هناك حاجة إلى الكثير من العمل المخصص.

اعتبارات التكلفة في ظروف مختلفة

في حين أن إنتاج البنود في المصنع يمكن أن يقلل من تكلفة العمالة والمواد ، فإن شحن الوحدات واستئجار رافعة لتجميع هذه البنود يمكن أن يضيف إلى التكلفة. في المشاريع الأصغر حجما أو المحلية ، يمكن أن تثبت التجميع في الموقع أن يكون الخيار الأرخص.

النقل والعوامل اللوجستية

بيوت الحاويات لديها مرونة جيدة جدا. يمكن شحنها بالجملة وفصلها لكل وحدة ، مما يبسط النقل والتجميع ويجعلها أكثر قابلية للتكيف مع مجموعة من ظروف الموقع. ويتيح هذا الترتيب تخطيط الخدمات اللوجستية التي يمكن تعديلها لتناسب إمكانية الوصول إلى الموقع.

ضمان الجودة وإدارة المخاطر

الوحدات المصنعة لها ميزة بيئة مسيطرة، مع احتمال أقل من العيوب. العمل في الموقع أكثر عرضة للخطأ البشري والمشاكل المتعلقة بالطقس ، على الرغم من مرونته.

التأثير البيئي والحد من النفايات

التصنيع المسبق رائع للبيئة. إنه يقلل من النفايات لأن المواد تستخدم بدقة كبيرة ، وإعادة التدوير هي حتى جزء من العملية. على الرغم من مرونته ، فإن البناء في الموقع يحتوي أحيانا على المزيد من نفايات البناء.

اختيار المنهجية المثالية لمشروع وحداتك

لاختيار أفضل طريقة للبناء ، تحتاج أولاً إلى اكتشاف ما يتطلبه مشروعك.

حجم المشروع وتعقيد التصميم

المشاريع الموحدة أو الكبيرة ، مثل مجتمعات كاملة من المنازل الجاهزة ، تستفيد أكثر من التصنيع الجاهز في المصانع. من ناحية أخرى، قد تتطلب البناءات المخصصة أو المعقدة للغاية المزيد من العمل في الموقع.

إمكانية الوصول إلى الموقع والظروف المحلية

إذا كان الموقع بعيدًا أو صعب الوصول إليه ، فقد لا يكون من الممكن نقل الوحدات المجمعة بالكامل. هذا سيفضل التجميع في الموقع أو تقسيم الوحدات لتسهيل التسليم.

قيود الميزانية وتوافر الموارد

المشاريع ذات الميزانية الصارمة غالبا ما تميل إلى التصنيع المسبق لتوفير المال. ومع ذلك ، قد يكون التجميع في الموقع هو المكالمة الأفضل إذا كان هناك الكثير من العمال المحليين المهرة المتاحة.

متطلبات التنظيم والامتثال

كما يمكن لقوانين البناء المحلية وقوانين تقسيم المناطق أن تشكل القرار. هذا صحيح بشكل خاص في المناطق المدنية أو المناطق التي لديها قواعد صارمة للغاية لتتبعها.

تطبيق في المنازل الجاهزة ومنازل حاويات الشحن

يتم استخدام كل من التصنيع المسبق في المصنع والتجميع في الموقع طوال الوقت في اليوم’ إسكان وحدات حديثة.

التصنيع الجاهز للمصنع في بناء المنزل الجاهز

خذ الفولاذ الخفيف الإسكان الجاهزة على سبيل المثال. استنادا إلى تصميم قياسي، يتم تصنيع أجزاء الصلب الخفيف في مصنع، وإحضارها إلى الموقع، ثم تجميعها في منزل كامل، مثل كتل البناء. هذا النهج يعمل بشكل جيد جدا للمنازل الجاهزة حيث يتم القيام به بسرعة ، والحفاظ على الاتساق ، والبناء على نطاق واسع هي الأهداف الرئيسية.

تجميع في الموقع في منازل حاويات الشحن الجاهزة

تتيح المرونة التي تأتي مع تجميع منازل الحاويات في الموقع العديد من الاستخدامات المختلفة والتغييرات المخصصة للموقع المحدد ، مما يجعلها مناسبة لجميع أنواع الظروف.

الجمع بين الطريقتين لتحقيق النتائج المثلى

يستخدم العديد من المشاريع في الواقع مزيجًا من الاستراتيجيتين. يقومون بتصنيع الوحدات القياسية مسبقاً ثم تجميع الأجزاء الأكثر تعقيداً في الموقع. وهذا يسمح لهم بالحصول على أفضل ما في كلا العالمين: الكفاءة وحرية التصميم.

متطلبات إعداد الموقع والتركيب

يعتبر إعداد الموقع خطوة حاسمة لنجاح تركيب وحدات.

أهمية أساس متصلب ومستوى

قاعدة متينة ومستوية هي المفتاح. يضمن أن الهيكل سليم ويجعل التجميع أسهل بكثير ، وخاصة للوحدات المتنقلة أو الجاهزة.

أنواع الأساس غير المناسبة والمخاطر المحتملة

تريد تجنب الأرض الناعمة أو غير المتساوية. يمكن أن يسبب عدم توافق الأجزاء ، مما يؤدي إلى مشاكل الصرف الصحي ، وخلق مشاكل هيكلية خطيرة في الطريق.

استخدام أركان الخرسانة أو أسس الأسمنت

اعتمادا على التصميم المحدد ، قد تستخدم رصيف الخرسانة أو لوحة أسمنتية كاملة للتأكد من دعم الهيكل بأمان.

دمج إطار المقطورة للتنقل

بعض المنازل المكونة من وحدات مبنية على إطار مقطورة. هذه الميزة تضيف قدرا كبيرا من التنقل وتجعل نقل المنزل أسهل بكثير.

تكامل أنظمة الطاقة والمرافق

اليوم’ تم تصميم المنازل المتكاملة للعمل مع جميع أنواع إعدادات الطاقة والمرافق.

اتصال إمدادات الطاقة القياسية بالشبكة الوطنية

معظم الوحدات مسبقا سلكية للاتصال الكهربائي القياسي، لذلك فهي متوافقة مع الشبكات الوطنية.

تركيب اللوحة الشمسية الاختياري بناء على احتياجات العميل

يمكن تثبيت الألواح الشمسية كميزة اختيارية. وهذا يوفر الطريق إلى استقلال الطاقة وأسلوب حياة أكثر استدامة.

الاعتبارات المتعلقة بنظام المياه والصرف الصحي

عادة ما يتم وضع أنظمة السباكة خلال مرحلة التصنيع المسبق. ثم ، يتم ربطها ببساطة بخطوط إمدادات المياه والصرف الصحي في الموقع.

تقديم Sunlit Tec: مورد موثوق للمنزل المتنقل

صنلايت تيك هو مزود رائد لحلول الإسكان الموحدة والمتنقلة ، مع سمعة قوية للابتكار والموثوقية.

نظرة عامة على عروض منتجات Sunlit Tec

Sunlit Tec لديها مجموعة متنوعة من المنازل المتنقلة. وتشمل عروضها كبسولات الفضاء وكبسولات التفاح ومنازل المجلس ومنازل الحاويات وحتى منازل صغيرة مصممة خصيصا.

التركيز على الجودة والتخصيص والمتانة

يتم بناء كل وحدة من المواد عالية الجودة. بالإضافة إلى ذلك ، يمكن تخصيصها لتتناسب مع احتياجات العميل ، مما يضمن أداء جيد ورضا لفترة طويلة.

أبرز الوحدات X5 و C2

نماذج مثل X5 و C2 تظهر حقا تفاني Sunlit Tec للتصميم الجديد ودمج التكنولوجيا الذكية والراحة العامة.

التزام بالتسليم الموثوق به ودعم ما بعد البيع

Sunlit Tec تعمل بجد لتسليم في الوقت المناسب. كما أنها توفر دعما ممتازا بعد البيع، مما يجعلها شريكا يمكنك الاعتماد عليه لأي مشروع سكني وحدات.

الأسئلة الشائعة:

س1: ما نوع الأساس المطلوب للمنازل المتنقلة لشركة Sunlit Tec؟

ج: تحتاج المنازل المتنقلة لشركة Sunlit Tec بشكل عام إلى أساس صلب ومستوى ، مثل لوحات الخرسانة أو الأعمدة. هذا يضمن استقرار الهيكل ويجعل عملية التثبيت تسير بسلاسة.

Q2: هل يمكن تجهيز منازل Sunlit Tec المكونة من وحدات بألواح شمسية؟

ج: نعم ، يتم تقديم الألواح الشمسية كميزة اختيارية. يمكن للعملاء أن يقرروا إضافة نظام شمسي بناء على احتياجاتهم من الطاقة ورغبتهم في الاستدامة.

س3: هل تقدم Sunlit Tec خدمات الصيانة أو الإصلاح؟

ج: Sunlit Tec يعطي دعم موثوق به بعد البيع. ويشمل ذلك خدمات الصيانة والإصلاح للحفاظ على سعادة العملاء وضمان استمرار منازلهم المكونة من وحدات لفترة طويلة.