في مشاريع هندسية مختلفة وبناء مخيمات مؤقتة وسيناريوهات أخرى ، تم استخدام صناديق التعبئة على نطاق واسع بسبب راحتها وعمليتها. تم تصميم صناديق التعبئة والتغليف لدينا وتكوينها مع مراعاة كاملة لاحتياجات الاستخدام الفعلية. فيما يلي مقدمة مفصلة لميزاتها المختلفة:

الأبعاد والمواصفات

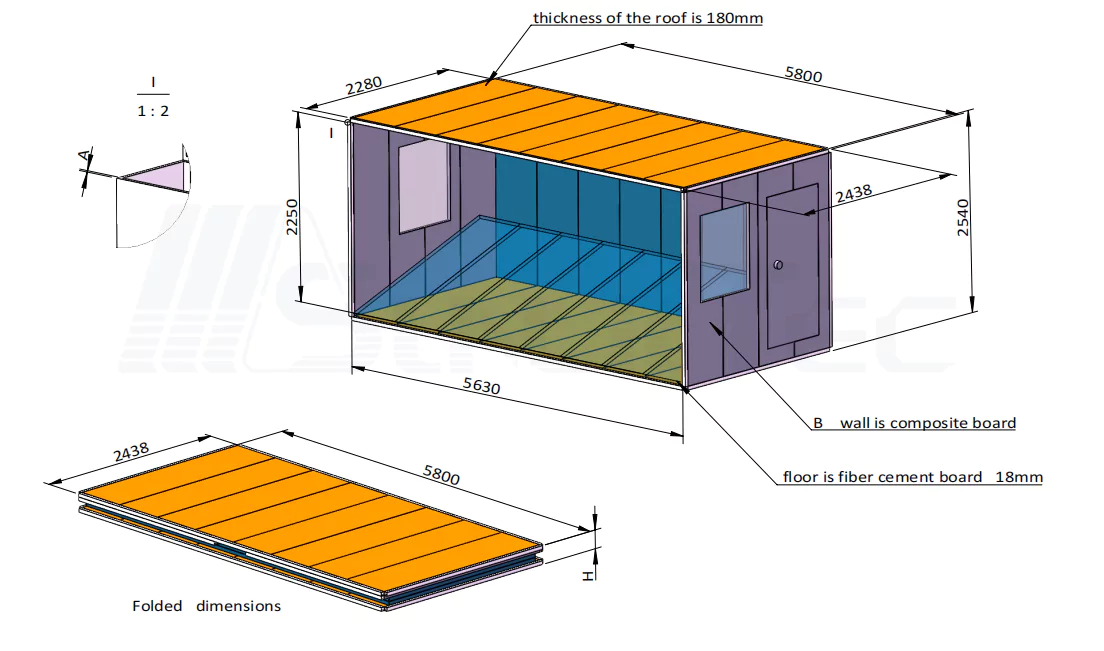

حاويات موقع البناء لدينا لديها تصميم قياسي الحجم، مع الأبعاد الخارجية من 580024502896mm والأبعاد الداخلية من 559022402500mm. هذه الأبعاد لا تضمن فقط وجود مساحة كافية في الداخل ، بل تسهل أيضًا النقل والتركيب ، ويمكن أن تتكيف بمرونة مع ظروف الموقع المختلفة.

تكوين المعدات الكهربائية

من حيث التكوين الكهربائي ، يتضمن تكوين الحاويات القياسي لدينا مقبسين من خمسة ثقوب ، ومقبس واحد من ثلاثة ثقوب ومفتاح رابط واحد. يمكن لهذه المقابس تلبية احتياجات استخدام المعدات الكهربائية اليومية ، ومفتاح رابط واحد مريح للسيطرة على الأجهزة الكهربائية مثل الإضاءة في الصندوق ، مما يوفر حماية مريحة لاستخدام الكهرباء في الصندوق.

تكوين الإضاءة

في التكوين الأساسي، صناديق التعبئة لدينا مجهزة بشريطين ضوئيين. الشريط الضوئي لديه نطاق إضاءة واسع وسطوع موحد ، والذي يمكن أن يوفر ضوء كاف في الصندوق ، وضمان تأثيرات إضاءة جيدة في فترات زمنية مختلفة ، وتلبية احتياجات الإضاءة للعمل اليومي والحياة.

تكوين الباب والنافذة

في التكوين القياسي ، تتضمن حاويتنا باب واحد ونافذتين. تصميم الباب يضمن الدخول والخروج العادي للموظفين ، ويمكن للنافذتين تحسين تأثيرات التهوية والإضاءة في الحاوية بشكل فعال ، مما يجعل البيئة داخل الحاوية أكثر راحة.

اختيار مواد العزل

سقف: يتم استخدام لفات الصوف الصخري للعزل. لفات الصوف الصخري لها خصائص عزل حراري جيدة ويمكنها منع الحرارة الخارجية بشكل فعال من دخول الحاوية. عادة ما يتم إغلاق الجزء السفلي من لفات الصوف الصخري ببلاط الأرضية ، مما يضمن تأثير العزل الحراري واستقرار السقف.

لوحات الجدار: يتم استخدام لوحات الصوف الصخري العادية ولوحات الرغوة. كلتا المواد لها خصائص عزل حراري جيدة وحفظ الحرارة ، والتي يمكن أن تقلل من تبادل الحرارة بين الحاوية والعالم الخارجي والحفاظ على درجة حرارة مناسبة في الحاوية.

الطابق: عادة لا يتم إجراء علاج العزل.

تكنولوجيا الهيكل والمعالجة

حاوياتنا تنتمي إلى فئة الفولاذ الخفيف وتتدلف على البارد بواسطة معدات خاصة. يمكن أن تضمن طريقة المعالجة هذه دقة وجودة الهيكل الفولاذي. الإطار مغلفن. يمكن لمعالجة الجلفنة تحسين مقاومة التآكل للهيكل الفولاذي بشكل كبير ، وتمديد عمر الخدمة للحاوية ، وضمان أنه يمكن الحفاظ على استقرار هيكلي جيد في بيئات مختلفة.

باختصار ، تسعى صناديق التعبئة والتغليف لدينا لتكون عملية وموثوقة في جميع جوانب التكوين ، ويمكن أن توفر حماية قوية لاحتياجاتك المختلفة. إذا كان لديك أي أسئلة أخرى، لا تتردد في التشاور.